Enhancing Chemical Feed Safety in Pool Maintenance

The article “Chemical Feed Safety” in the March/April issue of PoolPro was certainly a good start; however, there are several key chemical feed safety issues I believe can be added.

- Interlocks with recirculation flow

Some chemical controllers use other flow switches in addition to a pressure switch to monitor the presence of flow. Other detection devices include rotary flow and piston/magnetic contact units, which are critical controller features and should be tested daily.

Usually, the flow is detected in the sample stream loop, however, mechanical flow switches in the main recirculation plumbing can also be used.

- Interlocks with the recirculation pump power

In addition to hydraulic flow monitoring and interlock, several state and local environmental health codes call for an electrical interlock. This can be accomplished simply with a relay that controls the power to either the chemical controller or the actual chemical feed pumps connected to the power for the pump. The loss of power to the pump would open the circuit to the chemical control or feeders.

IDEALLY, BOTH FLOW SWITCHES AND POWER INTERLOCKS SHOULD BE IN PLACE.

- Anti-siphon valves

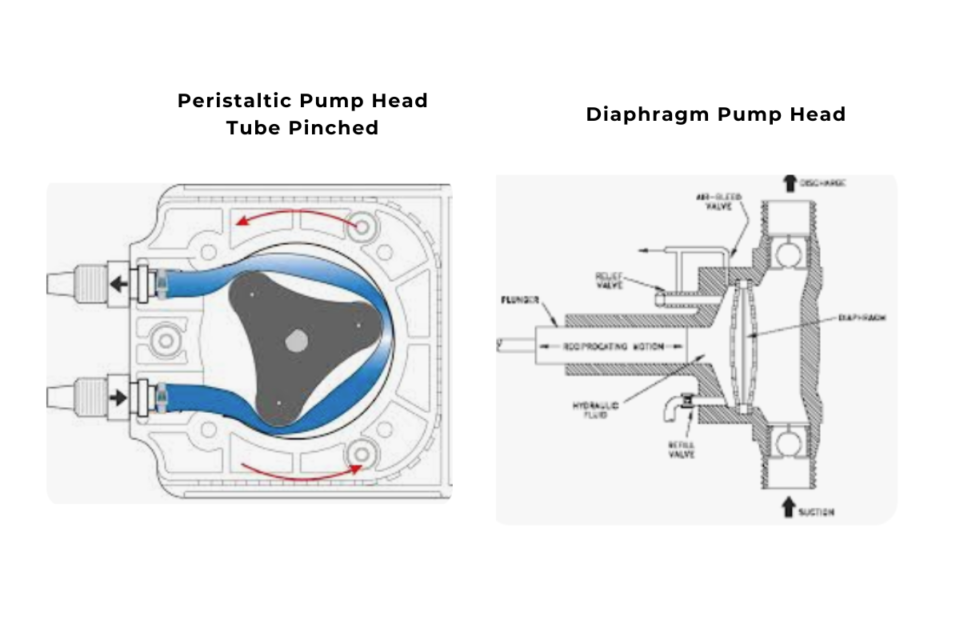

There are several types of chemical feed pumps, with peristaltic being the most common. One feature of peristaltic feed pumps is that the chemical feed tube is “pinched closed” in the pump head, preventing any backflow of pool or spa water but most importantly, preventing chemical siphoning from the chemical container or drum.

However, diaphragm pumps can allow flow through the pump head and by the diaphragm. In most cases, the chemical storage tank or drum sits above the level of the swimming pool. If the power is lost, the recirculation pump is turned off or the pump loses prime, chemicals can be siphoned from the storage tank into the recirculation plumbing via the chemical feed line. Liquids always seek their lowest common level.

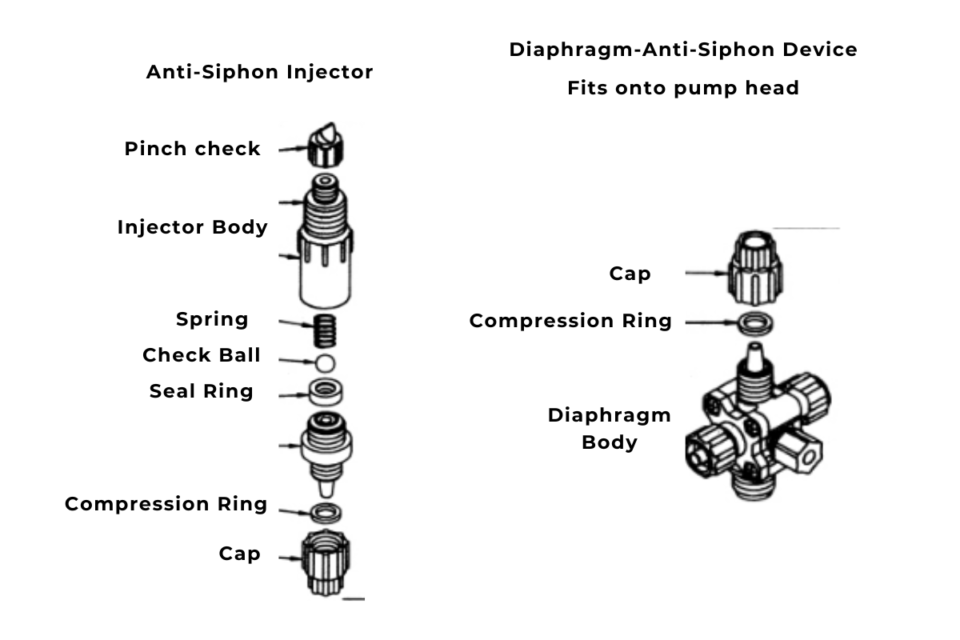

Remember, a check valve is NOT an anti-siphon valve. Most anti-siphon valves make use of a check ball and spring. The spring must be overcome by pressure from the diaphragm pump to pass any chemical. This siphoning issue can happen to both liquid chlorine and acid or acid feed solutions.

If chlorine and acid are allowed to mix in the recirculation return line, chlorine gas is formed. When the recirculation flow is re-established, the chlorine gas will travel out to the pool or spa, which can cause serious injury and even death.

Anti-siphon devices are a must on diaphragm-type pumps. There are two major in-line: spring/ball check units and diaphragm units.

- Flow indicators

Another important pump feature not often found in chemical feed pump applications is an in-line flow indicator. This relatively inexpensive feature can help operators and service technicians troubleshoot chemical feeder operations and take action before problems become disasters by observing the indicator ball. This does not actually measure the flow but indicates flow is present.

This flow indicator can show several issues.

- When bubbles appear in the indicator, the problem is most often that the chemical container is out of chemicals. It might also note air entering the line from a suction leak in the supply tubing.

- When the flow indicator shows no movement when the pump is operating, this can show there is an issue with the pump feed tube on a peristaltic pump or there is a broken diaphragm in other pumps.

- If the flow indicator ball begins to rise and then slams down to the bottom, this is a sign the chemical injector is clogged.

Stenner and Blue-White are readily available through distribution:

By having a flow indicator, troubleshooting chemical feed equipment is made far easier.

- Double containment

Article 80 of the Uniform Fire Code calls for double containment of chemical lines that carry hazardous chemicals. Double containment will stop or limit any chemical leak in a feed line. This is especially important for lines on the discharge or pressure end of chemical feed pumps on their way to the injector.

This can be accomplished by having the primary carrier installed inside another tube. Often, it can be as simple as installing the pressure line inside a larger, clear, vinyl tube so the primary line can be examined for leaks. If this is installed from the discharge end of the pump to the chemical injector, then any leak would be limited only to the two ends of the secondary line.

- Proper labeling

Article 80 of the Uniform Fire Code calls for labeling of:

– All chemical feed tanks or containers

– Chemical feed pump

– Chemical feed line

– Chemical injector

Common “chlorine and acid” labels are available, and many are even colored (i.e. yellow for chlorine and red for acid) with letters of contrasting color.

- Safety Data Sheet library

OSHA, Article 80 of the Uniform Fire Code and Federal Right To Know Code all call for Safety Data Sheets to be readily available for operators and service techs so they know what health hazards, reactivity and spill procedures they’re dealing with.

8. Use the right materials for the chemical

Too often, we find inappropriate container types, injectors and chemical feed lines in use, made from materials that are not compatible with the chemicals being stored or fed. The most common examples include:

– Plastic trash cans storing chlorine or acid

– Copper, brass or nylon injector fittings

– Low-pressure vinyl tubing for pressure feed lines

Always consult the chemical feed manual and or the appropriate chemical Safety Data Sheet.

9. Install proper National Fire Protection Association placards on doors. These are part of the Uniform Fire Code Article 80 requirements and warn firefighters of possible dangers in a chemical or mechanical room.