Got Check Cracks? Check Wind Speed.

In December 2023, the National Plasterers Council released Technical Bulletin No. 8, highlighting the impacts of wind speed on plastic shrinkage, or check cracks, in pool plastering. While the harmful effects of hot temperatures, low humidity, high winds or a combination of these are known, the study underlines wind speed as the dominant variable. The NPC says the findings are crucial for reducing check cracks and improving plaster durability.

“This research holds practical value for pool plasterers in managing environmental conditions during application,” says Chris Marcano, executive director of the NPC. “By identifying wind speed as the primary factor in water loss and plastic shrinkage cracking, pool professionals are better equipped to mitigate common issues.”

By identifying wind speed as the primary factor in water loss and plastic shrinkage cracking, pool professionals are better equipped to mitigate common issues.”

Chris Marcano, National Plasterers Council

Marcano says the new bulletin builds on findings in Bulletin No. 6, released in November 2019, which covers five dominant factors that cause abnormal water loss at the upper surface and increase the potential for abnormal drying shrinkage to occur.

These factors are: temperature of the ambient air, temperature and absorption rate of the substrate, temperature of the plastering materials, humidity of the ambient air and wind speed.

While wind speed was listed in 2019, bulletin No. 8 elaborates on its impacts. Marcano says it’s the interaction of factors — especially sustained wind speeds — that play a significant role in water loss from the plaster surface. These findings underscore the importance of controlling wind exposure on jobsites to avoid premature drying, which leads to check cracking.

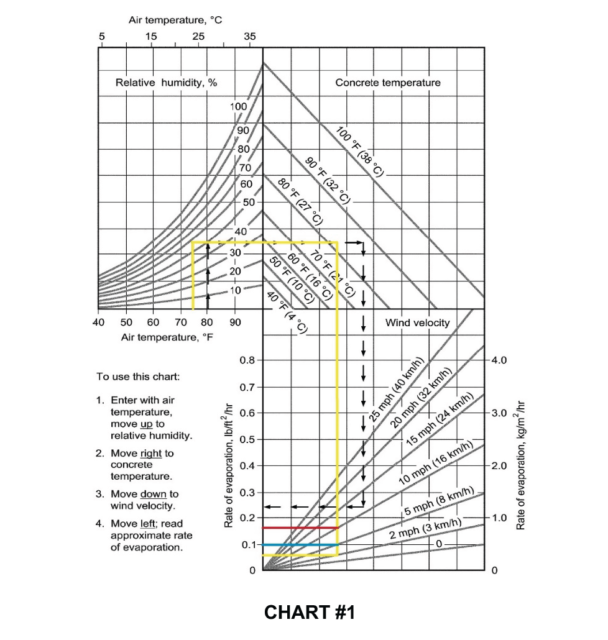

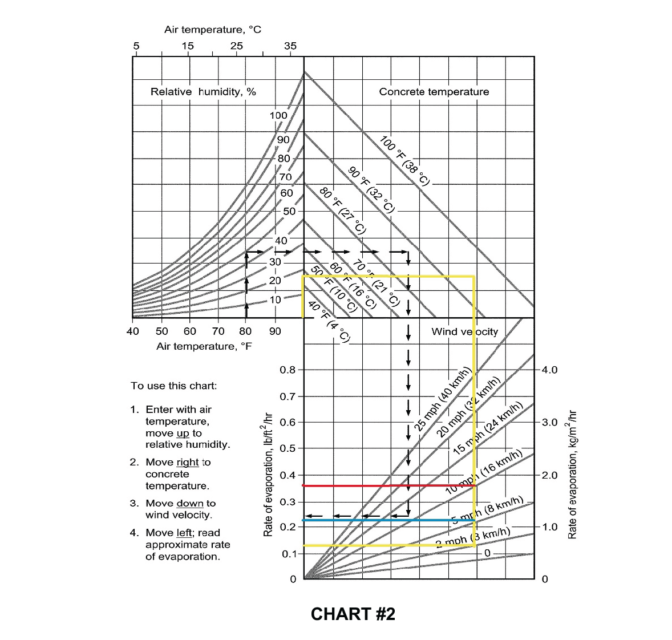

To illustrate this, bulletin No. 8 shows nomograph charts that combine the effects of air temperature, relative humidity, material temperature and wind speed that cause abnormal upper-surface water loss and result in abnormal plastic shrinkage. The nomograph charts are highlighted in yellow, blue and red to show three different wind speeds on a day with a normal temperature and on a day with a high-temperature condition. The bulletin explains that any result where the maximum evaporation rate exceeds 0.2 lb/yd2/Hr is likely to experience abnormal cracking.

On hot days (100 F) with low humidity (20 RH), the critical upper-surface water loss level leading to plastic shrinkage cracking is not reached until wind speeds exceed 5 mph. In moderate temperatures (75 F), plaster can still experience abnormal water loss if sustained winds exceed 10 mph.

These findings show wind speed is the key driver in shrinkage cracking.

The study aligns with what many have experienced in the field, says Rob Romano, general manager at David Cooke Plaster Co. and president of the Northeast Spa & Pool Association.

“When I deal with check cracks, there’s typically two reasons,” Romano says. “First, it took two or more days to fill the pool. Or second, if you go back and look at the weather, it’s the wind.”

The NPC bulletins provide steps to reduce the likelihood of check cracks. They include:

- Prewetting the substrate. This reduces substrate absorption, ensuring more consistent drying.

- Optimizing equipment and workforce. This ensures equipment is ready to avoid delays and there are enough skilled plasterers to work within limited timeframes.

- Timing and material adjustments. Plastering in cooler parts of the day, using cold water in the mix and considering set retardants can extend finishing times and reduce shrinkage risks.

The bulletins provide additional jobsite guidance and considerations for hot weather that also apply to conditions where wind speed is a concern.

- Use light-colored pump hoses or lay white or light-reflecting tarps over hoses, the cement and sand/aggregate.

- Reduce the absorptive capacity of the substrate and produce a more uniform drying time by applying a separate preplaster coating such as a brown or bond coat.

- Tent the pool.

- Reduce the temperature of the material (use cold water or ice; tarp materials).

- Use a slower-setting cement.

- Use a pozzolan or other supplementary material.

- Use a set retardant.

- Use supplemental (retemper) mix water to offset water loss.

- Use water reducers.

“These valuable findings are an opportunity to strengthen industry practices by raising awareness around the impact of wind speed on plastic shrinkage,” Marcano says. “With this research, pool plasterers can proactively adapt their techniques to minimize issues and improve plaster durability.”

One technique Romano’s crews use is prewetting the surface.

“First, you need to do that to have the correct adhesion between the plaster and the pool,” he says. “But also, it holds some of that moisture in with the finish. If it’s been sitting for too long and the shell is dry, it’ll pull the moisture out of the finish.”

Romano says another way to avoid losing moisture, particularly on a windy day, is to have water trucks on standby to fill the pool as soon as possible and help mitigate the risk of check cracks.

By promoting these insights across the industry, Marcano says the NPC aims to support professionals in achieving more consistent, high-quality results, which ultimately enhances the lifespan and appearance of plaster finishes. “This research encourages the adoption of preventive measures that benefit the entire field,” he says.

Romano advises plasterers and professionals to read technical bulletins to stay informed. He also highlights the value of organizations like the NPC, which provide best practices that may vary across regions due to differing climates. It’s crucial to study and understand your local weather patterns and not just focus on temperature but also consider other environmental factors, Romano adds.

“We take for granted that we’re looking for temperatures and wind sometimes becomes secondary because you’re so worried about your window to get these pools done in a particular timeframe,” he says.

Though there are many practices to help prevent check cracks, Romano notes there is no one-size-fits-all solution.

“It’s a skill,” he says. “It’s not like you can say, ‘OK, the wind speed is this and the temperature is that, therefore I have to put this much in there,’ because every pool tells a different story. It’s all up to the experience of the foreman and the trowelers and what the finish is telling them.”